This weblog publish is sponsored by Bluezone, the unbiased present for denim and sportswear by Munich Cloth Begin. Register for the subsequent present right here!

Bluezone’s Keyhouse Is The place the Newest Tech and Craftsmanship Collide within the Way forward for Denims

Denim fanatics know there’s magic within the previous methods. Stiff uncooked denim, slubby yarns, and rope-dyed indigo all tie again to time-honoured traditions.

However are you aware who—or what—is definitely making your denims? Robots and AI are shaking up denim manufacturing, however can they actually replicate the human contact that we fanatics love a lot?

On the Bluezone denim commerce present by Munich Cloth Begin, the way forward for denim takes centre stage. The applied sciences showcased on the upcoming January 2025 version of the present will spotlight simply how a lot innovation is shaping the best way denims are made.

However innovation doesn’t should imply the top of custom. The true query isn’t whether or not expertise is altering denim—it’s the way it’s reworking the best way denims are made whereas staying true to their roots.

The place Denim Tech Is Already at Work

Know-how is reshaping denim manufacturing in methods each delicate and revolutionary. However a lot of what we take into account “conventional” denim is already formed by fashionable instruments that scale manufacturing, scale back prices, and enhance sustainability—all whereas preserving the essence of genuine craftsmanship:

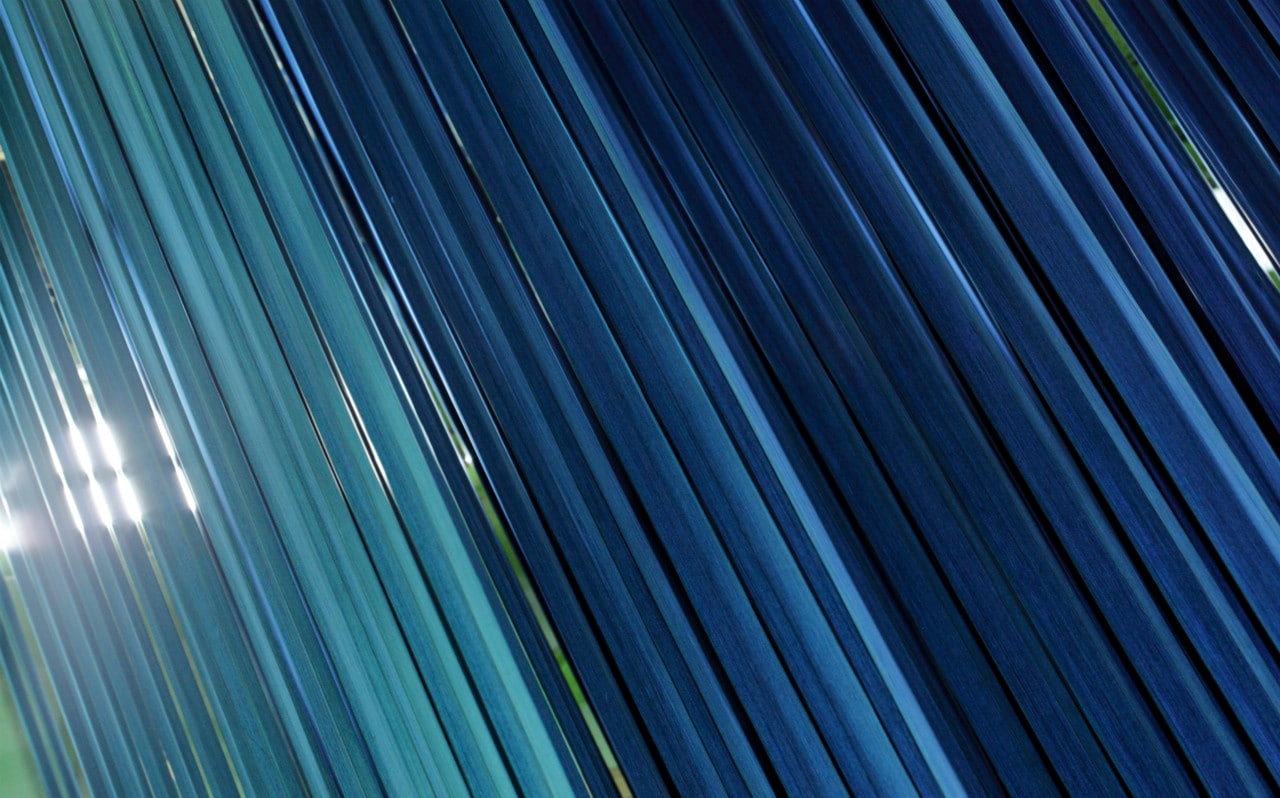

Indigo Dyeing

One space seeing speedy innovation is dyeing. Conventional rope dyeing has lengthy been the hallmark of premium denim, however newer strategies like foam and spray dyeing are altering the sport.

These processes rely closely on robotics for precision software, lowering water utilization by as much as 90% in comparison with older methods. This not solely conserves sources but additionally provides manufacturers higher management over color consistency—making certain every pair of denims comes out good.

For extra about how dyeing has developed, take a look at our indigo information.

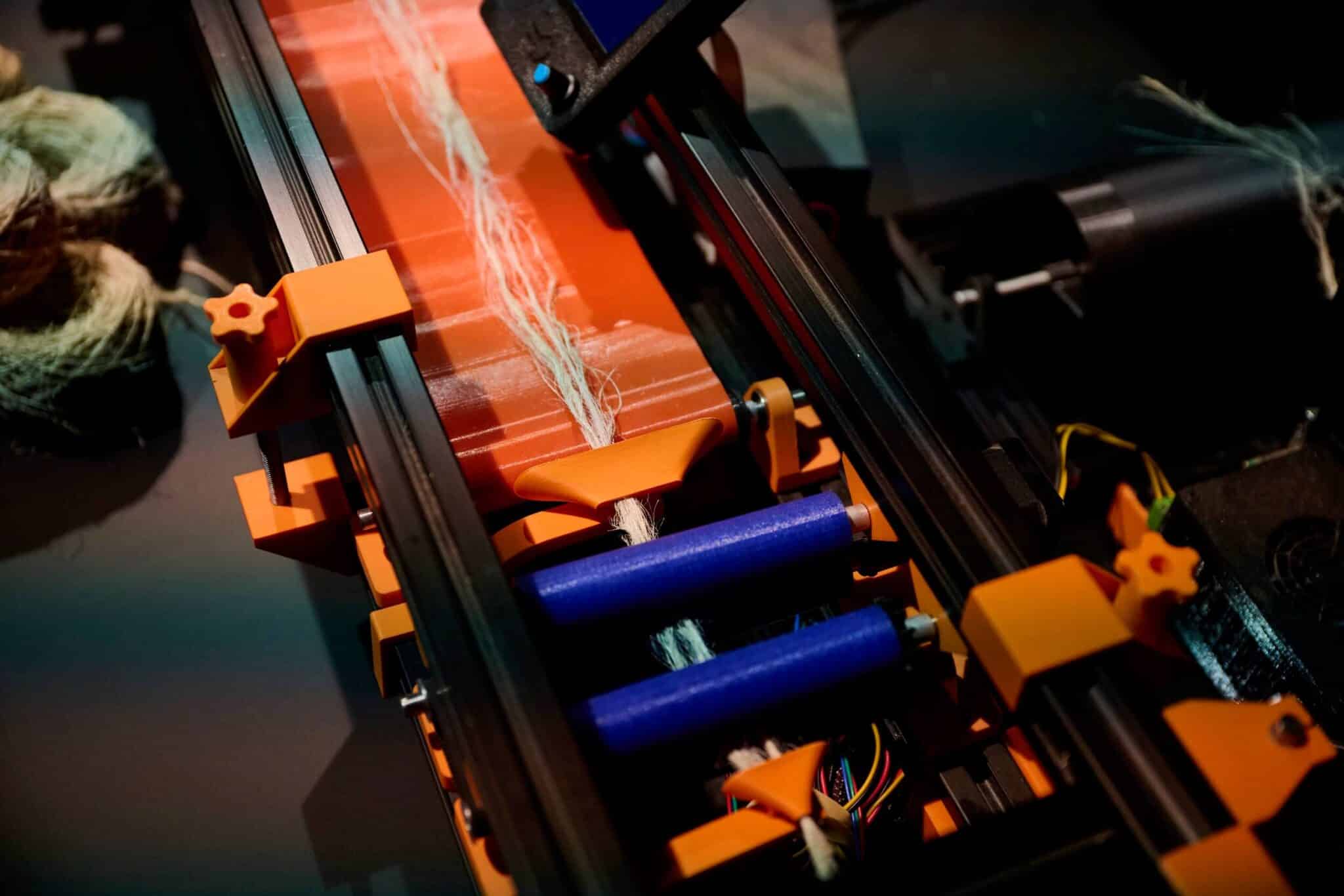

Spinning

In yarn spinning, conventional strategies like ring spinning, which creates the slubby textures denim fanatics love, are mixed with fashionable open-end spinning for pace and effectivity. Curious concerning the variations?

Study extra in our publish on how denim is spun.

Weaving

There’s been an identical evolution in weaving.

Whereas most denim immediately is made on shuttlemuch less looms for scalability, the resurgence of shuttle looms for selvedge denim proves that high quality craftsmanship stays in demand.

In the event you’ve ever puzzled why selvedge denim is so prized, examine it in our publish on how denim is woven.

Lower & Sew

In slicing and sample placement, laser-guided machines carry unimaginable precision. These programs can slice via a number of layers of denim with minimal waste, making certain every bit is completely reduce.

Robotics are additionally making an affect in stitching operations, notably for repetitive duties like attaching belt loops or bartacking. Automation excels at these high-precision steps, liberating expert employees to give attention to extra intricate particulars.

Finishes

Ending processes have maybe seen probably the most seen transformation.

Laser fading, as an example, replicates years of wear and tear in mere minutes, creating intricate whiskers and fades with out water or chemical compounds. Ozone therapies and enzyme washes ship lived-in appears with minimal environmental affect.

In the event you’re interested by pre-washing, learn extra in our publish on how denims are pre-washed.

The place People Nonetheless Reign

Regardless of all of the advances, denim nonetheless has its quirks—and robots and expertise have their limits.

Versatile materials like denim are notoriously difficult for machines to deal with, which means many steps within the manufacturing course of nonetheless rely closely on human fingers, comparable to:

Stitching

Take stitching intricate seams like chain-stitched hems.

These particulars, treasured by fanatics, are exhausting for robots to duplicate as a result of they require the dexterity and instinct of a talented craftsperson.

Variations in denim thickness, stretch, or rigidity can throw off machines, whereas human fingers instinctively adapt, making certain that every sew is good.

QC

High quality management is yet one more space the place people excel.

Whereas AI can detect seen flaws, the contact and instinct of a talented employee can decide up on points—like inconsistent rigidity or delicate imperfections—that machines typically overlook.

This hands-on method ensures that each pair meets the requirements fanatics count on from high-quality denim.

Dyeing

Even the artwork of indigo dyeing, whereas modernised in some areas, stays rooted in methods that machines wrestle to duplicate authentically.

Rope dyeing, for instance, requires an skilled operator to guage the timing of dips and drying, making certain the right steadiness of deep indigo tones with a crisp white core. These delicate choices, based mostly on experience somewhat than automation, protect the magic of conventional indigo.

For all its developments, expertise nonetheless serves finest as a complement to human talent, not a substitute. It’s the mix of artisan experience and fashionable instruments that retains denim’s traditions alive whereas making certain it could evolve for future generations.

A Glimpse on the Innovators Shaping Denim at Bluezone

The applied sciences shaping denim manufacturing immediately are already spectacular. However they’re only the start.

At Bluezone, the Keyhouse sub-show is the place custom meets innovative. It’s develop into the beating coronary heart of the occasion, drawing consideration to the improvements and producers which might be reworking the denim business.

Among the many many exhibitors on the present, these exhibitors exemplify the fusion of custom, sustainability, and cutting-edge developments that outline the way forward for denims:

Calik Denim

Calik Denim leads the cost with water-saving dyeing methods and circularity-focused manufacturing. Their collections steadiness softness and sturdiness, utilizing recycled fibres and eco-conscious dyes to make sure their materials are as sustainable as they’re trendy.

ISKO

ISKO’s Luxurious by PG line redefines denim luxurious by merging technical innovation with high-end aesthetics. Their dedication to sustainability and inclusivity ensures their designs ship each magnificence and duty.

Sharabati Denim

From the slubby textures of GOOD OLE to the biodegradable blends of RELIVE, Sharabati Denim showcases a various vary of sustainable choices. With daring prints in COOLR and stylish softness in VERSO, they show that artistry and eco-consciousness can coexist fantastically.

Tejidos Royo

Tejidos Royo’s DRY SUN assortment is a testomony to the chances of innovation. Their DRY Colors expertise eliminates wastewater whereas lowering water and power consumption, delivering rustic but fashionable materials crafted from pure fibres like linen and TENCEL™.

Normal Traits Shaping Denim’s Future

Past these highlights, broader traits are reshaping how denim is made:

- Blockchain expertise, for instance, is offering higher transparency within the provide chain, permitting clients to hint their denims again to their origins.

- Digital design instruments are lowering waste by digitising sampling, enabling producers to finalise designs with out the necessity for bodily prototypes.

For uncooked denim fanatics, it’s straightforward to really feel apprehensive concerning the function of expertise in denim’s future. However these improvements aren’t erasing what makes denim particular—they’re preserving it.

The slubby textures, wealthy fades, and sturdy constructions that outline uncooked denim at the moment are being achieved extra sustainably and effectively.

Know-how isn’t changing heritage; it’s serving to make sure that denim’s timeless attraction can thrive for generations to return.

Wish to Know Extra About Denim’s Future?

Robots are taking up increasingly more of the heavy lifting in denim manufacturing, particularly the place pace, precision, and sustainability are involved. However for now, the center and soul of denim—the imperfect perfection—nonetheless belong to the expert artisans who work alongside the machines.

Bluezone is the place custom and innovation collide—from the most recent applied sciences at Keyhouse to the broader traits shaping the denim business. Whether or not it’s robots, AI, or sustainable practices, this present and its exhibitors are driving these modifications.

Share